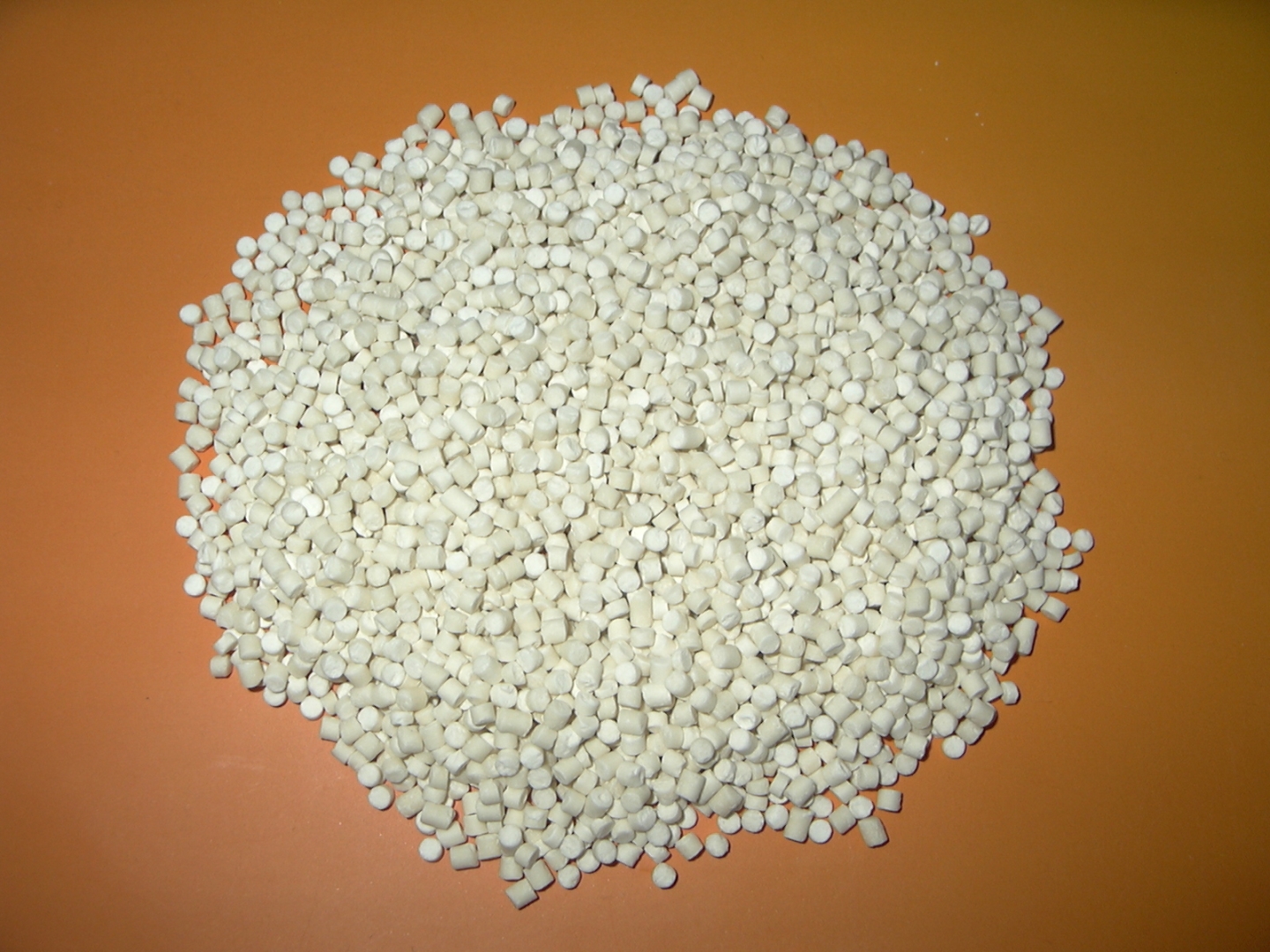

Dust Less Blends (DLB) is free-flowing pellets of various polymer additives based on various formulations. DLB consists of antioxidants, acid scavengers, nucleating additives, UV stabilizers, neutralizing additives and other additives according to specification of the desired final product. DLB is 100% of additives without any polymer resin or intermediates.